What are the commonly used ventilation equipment in air conditioning engineering of vent actuators

1. Ventilator

Commonly used ventilators are: general purpose ventilator, dust exhaust ventilator, high temperature ventilator, explosion-proof ventilator, anti-corrosion ventilator, anti-smoke ventilator, roof ventilator and jet ventilator.

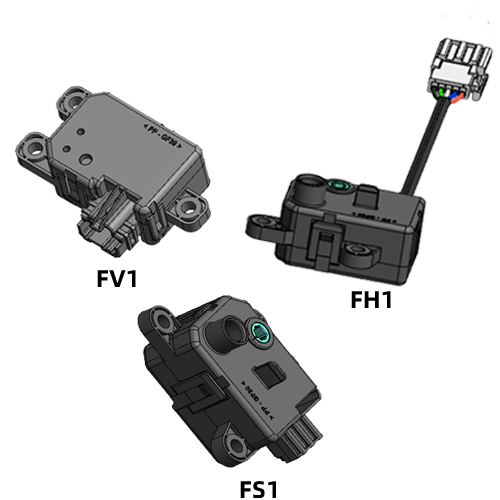

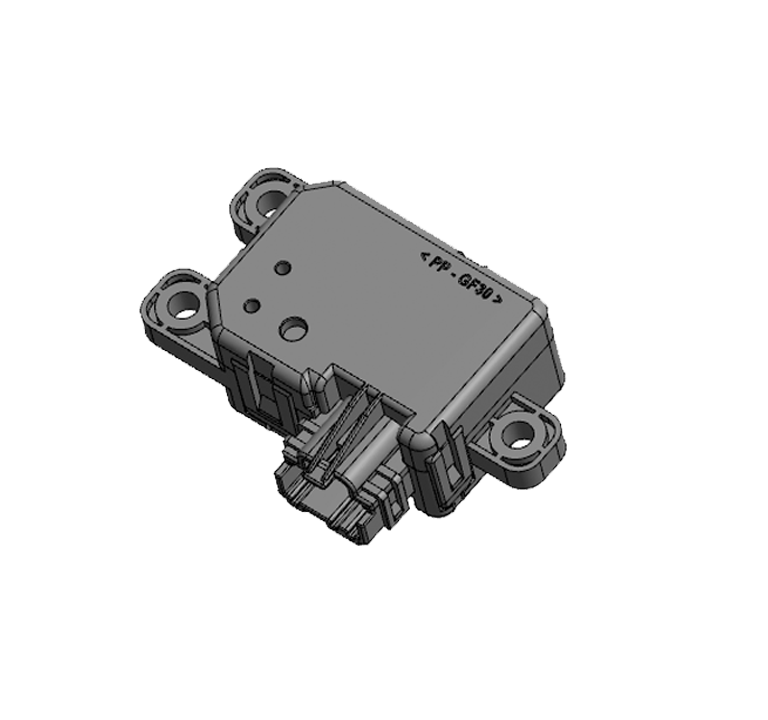

2. Damper

The air valve in the ventilation and air conditioning system is mainly used to start the fan, close the air duct and air outlet, adjust the air volume in the pipeline, and balance the resistance. The regulating valve is installed in the air duct of the fan outlet, the main air duct, the branch air duct, or before the air distributor. In the ventilation and air-conditioning project, according to the different functions of the regulating valve, there are multi-leaf regulating valves, fire dampers, butterfly valves, check valves, rectangular air duct three-way regulating valves, closed inclined flap valves and start valves.

3. Air outlet

The tuyere is an important part of the ventilation system. Its function is to send a certain amount of air to the place where the gas is used or discharge it from the exhaust point according to a certain flow rate. Aluminum alloy vents are the most widely used in ventilation (air conditioning) projects. The surface is oxidized and has good anti-corrosion and waterproof performance.

At present, the commonly used air outlets are grille air outlets, floor return air outlets, slotted air outlets, louver air outlets (fixed blind air outlets, movable blind air outlets) and diffusers.

According to the specific function, the air outlet can be divided into new air outlet, exhaust air outlet, air supply outlet, return air outlet, etc. The fresh air inlet sucks the outdoor clean air into the pipe network; the exhaust port discharges the indoor or pipe network air to the outside; the return air inlet sucks the indoor air into the pipe network; the air supply port sends the air in the pipe network indoors.

4. Local exhaust hood

The main function of the exhaust hood is to remove dusty gas, residual heat, residual humidity, poisonous gas, oil fume, etc. in the process or equipment. According to different working principles, local exhaust hoods can be divided into the following types:

(1) Airtight hood: All the harmful substances are sealed in the hood, and air is sucked from outside the hood to keep the negative pressure inside the hood. Only a small amount of exhaust air is required to effectively control harmful substances. The airtight cover used for the dust removal system is also called the dustproof airtight cover.

(2) Cabinet-type exhaust hood: The structure is similar to that of the airtight hood, except that one side of the hood is fully open. Large indoor fume hood, the operator can directly enter the cabinet to work.

(3) External suction hood: Use the action of exhaust air flow to create a certain suction speed at the place where the harmful substances are emitted, so that the harmful substances are sucked into the hood.

(4) Receiving exhaust hood: Some production processes or equipment themselves will generate or induce a certain airflow movement, such as convective airflow on the upper part of the high temperature heat source. Harmful substances will enter the hood directly with the airflow.

5. Dust collector

There are many types of dust collectors. Generally, they can be divided into six categories according to the main dust removal mechanism: gravity, inertia, centrifugal, filtration, washing, and static electricity; according to the degree of gas purification, they can be divided into coarse purification, medium purification, fine purification and According to the dust removal efficiency and resistance of the dust collector, it can be divided into high-efficiency, medium-efficiency, coarse-efficiency and high-resistance, medium-resistance, and low-resistance.

6. Muffler

A muffler is a device that blocks the transmission of noise while allowing airflow to pass smoothly. In ventilation and air conditioning systems, mufflers are generally installed on the horizontal main air duct at the fan outlet to reduce the aerodynamic noise generated by the fan. There are also mufflers installed in the elbows in front of each air outlet to prevent or reduce the spread of noise from the air duct to the air-conditioned room. There are many structures and types of mufflers. Commonly used mufflers include impedance composite mufflers, tubular mufflers, micro-porous plate mufflers, chip mufflers, folding plate mufflers, and muffler elbows.

7. Air Curtain

The bar-shaped air distributor is used to eject a curtain-like airflow with a certain speed and temperature, so as to close the doors, halls, passages, door openings, counters, etc., to reduce or isolate the intrusion of external airflow, so as to maintain the indoor or a certain working area. Environmental conditions, Colleagues can also block the entry of dust, harmful gases and insects. The thermal insulation, cold insulation, dust insulation and insect insulation properties of the air curtain can not only maintain the indoor environment but also save building energy consumption.

The air curtain can be composed of air handling equipment, fan, air duct system and air distributor. According to the installation position of the air distributor, the air curtain can be divided into three types: upper feeding type, side feeding type and downward feeding type; according to the heating state of the air supply air, it can be divided into non-heating air curtain and hot air curtain.