What is the difference between electric and pneumatic actuators?

Actuators generally include pneumatic actuators, electric actuators and hydraulic actuators. The general definition of the actuator is: can provide linear or rotational motion of the driving device, can use the driving energy, under the action of control signals, automatic operation of some equipment and devices, control their switch and regulation, rather than manual operation. An execution unit is a terminal control unit in the process control industry, usually consisting of a valve and an actuator. The electric actuator controls its operation through various currents, while the pneumatic actuator controls its operation through air pressure.

In the production process of various industries, the actuator is an indispensable machine, according to the application environment and industry can be divided into electric actuator and pneumatic actuator two categories. The functions of the two actuators are almost identical, but they are otherwise quite different. Here are some of the differences.

One, how easy it is to get the driver source

(1) Electric actuator: the driving source is a power supply, whether it is a three-phase power supply or a single-phase power supply, which is easy to obtain in the industrial site.

(2) Pneumatic actuator: the driving source is the air source, which requires special supporting air source station and pipeline laying, complicated construction and increased budget. The air source is generally compressed air, so a large air compressor is needed.

All kinds of industrial sites have easy access to electricity. It is more convenient to use electric actuators for some small equipment (usually small equipment without compressed gas, such as plate press, shield machine, etc.).

2. Conservation of energy

① Electric actuator: only when the opening of the control valve changes, it is necessary to drive the motor. When the required opening is reached, the motor will be powered off. In standby mode, only a small amount of power is needed to keep the control unit operating.

(2) Pneumatic actuator: in the whole control valve work and standby state, all need a certain pressure. When the air pressure drops, the compressor will be pressurized.

In general, electric actuators are more energy efficient than pneumatic actuators.

Third, technical differences

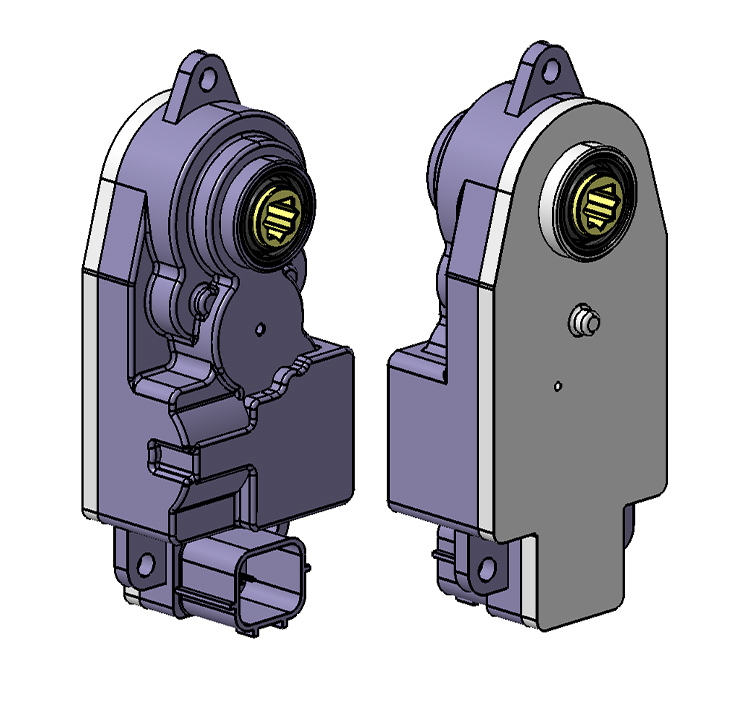

The obvious difference between pneumatic and electric actuators is their technical difference. The overall structure of the pneumatic actuator is uniform, so its load capacity is good, and because it uses gas as its power source, it is particularly suitable for high torque output. The size of the electric actuator is relatively small, and the structure is simpler than the pneumatic actuator, so from the technical point of view, the equipment is easy and the power drive is flexible.

Four. Differences in use environments

The different operating environment is also one of the important differences between the pneumatic actuator and the electric actuator, which is also caused by the different structure and power of the two. In general, pneumatic actuators do not require high working conditions, and can even be used in explosive, magnetic and gas contaminated environments. However, the electric actuator has requirements on the environment, and the requirements of the environment should be strictly complied with.

It can be known from the basic characteristics of the electric actuator that there is a great difference between the electric actuator and the pneumatic actuator. Among them, the three obvious differences are their structure, technical level, use environment, etc. , but these will not affect the use, because the two actuators are used in different fields.

Conclusion: Electric actuator has more advantages in selection, compact structure and small size. Compared with pneumatic actuators, electric actuators are relatively simple in structure, easy to take energy, no danger of "air leakage", and high reliability. The performance of electric valve is higher than that of pneumatic valve. After all, the motor drives the valve, so it will have more torque. This can adapt to more working conditions, and the electric valve in the valve type is no longer limited to the Angle stroke, can be used for gate valves, globe valves and other straight stroke valves.